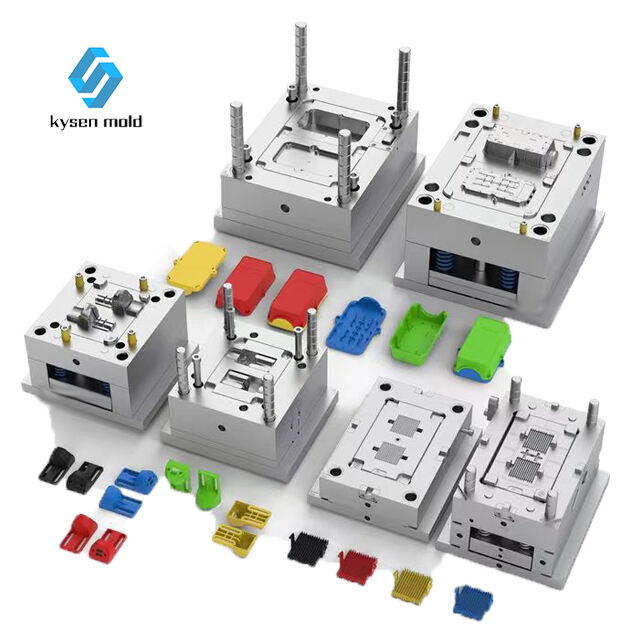

injection molding production

The injection molding production is a manufacturing process that involves injecting molten material into a mold cavity, where it cools and solidifies to form a desired product. The main functions of injection molding include shaping, forming, and producing intricate parts and components with high precision. Technological features such as computerized controls, automated robotics, and advanced mold designs contribute to the efficiency and accuracy of the process. Applications of injection molding are widespread, including automotive parts, medical devices, consumer goods, and electronics. The ability to produce complex shapes and high-volume production runs makes it a versatile and cost-effective solution for various industries.